This is a post I made almost two years ago. I hadn't been able to shoot much since then, but now range access and a group to shoot with has become available.Tzed250 wrote:My IZH had a habbit of doubling every once in a while. It doubled consistently with Federal 711B. After reading several articles on the subject, I decided to examine the gun. I stripped the pistol and used a 10X Coddinton magnifier to check the bolt face. Sure enough, it had quite a bit of peening. A few careful minutes with an X-acto knife and a stone removed the burrs. I took it to the range and fired about 200 rounds. No doubling, but there were two failures to eject. I blamed this on chilly temps (about 55 deg.). Another trip to the range, this time with temps in the mid 70s, showed perfect functioning. I will report more when the pistol has more rounds through it.

As soon as I started to put more rounds through my IZH the doubling problem returned. I tried adjusting the trigger, cleaning, different ammo, and even the O-ring buffer in an attempt to make the pistol reliable. No go.

I then measured the headspace for the cartridge rim on the bolt. It measured .040". This was done by using a 1" micrometer across the top and bottom of the bolt face. I knew this was insufficient. The problem is getting a tool to the bolt face to cut the recess for the rim. I ended up finding an old .5" reamer. I cut the fluted section from the tool, then chucked the body in a lathe where I drilled and reamed a .375 bore to hold a 17/64 (.266) four-flute center-cutting end-mill. The .5" reamer was a MT1 mount, so with a MT1-MT2 adapter I was able to mount it in my drill press.

This tool length gave me the ability to reach the bolt face while clearing the rest of the bolt.

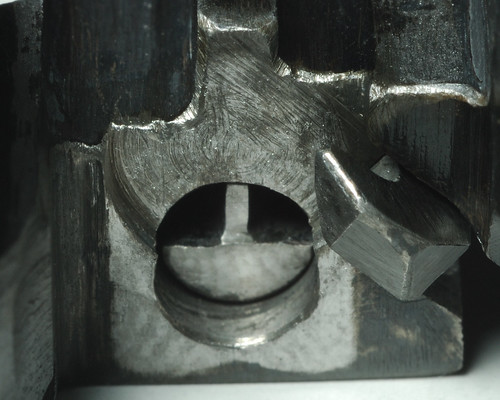

The end-mill is shown here:

The following pictures show the bolt face after machining. The headspace was increased to .046". The firing pin is shown in the ready and fire positions.

On Sunday I went to the range and fired a mix of Remington Subsonic, Remington 22 Target, and Eley Sport, all ammo that had doubled in the pistol previously.

After 300 rounds of slow and rapid fire the pistol did not double one time.

I hope that this has put the reliability of the IZH where it should be, and I will monitor the headspace to ensure it does not enter back into the danger zone.

Questions and comments are welcome.

John.

.